I can't speak to all oil formulations. Generally speaking, motor oils are designed to work in hot engines for a long time, and so should be quite stable at ambient temperatures for years if properly stored. How many years may vary per oil, but personally I would be comfortable up to five years for a modern certified oil. I would shake the bottle before using in case any additives settled out.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Notatka: This feature may not be available in some browsers.

-

Cytatów używajcie tylko jeżeli jest to potrzebne! Jeżeli chcecie komuś odpisać używajcie @ z nazwą użytkownika.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Informacje na temat estrow oraz ogolna wiedza - Na pytania odpowie Thomas Schaefer (TomNJ)

D

Deleted member 925788

Gość

Do you know this chemical? If so, what is your opinion?

D

Deleted member 925788

Gość

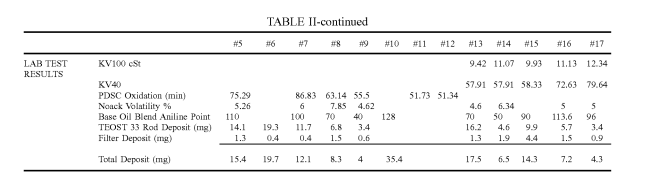

Do you know this kind of POE? They look very good in combination with the PAO, especially in terms of deposit control. Although the AP is relatively high, it means that this parameter does not affect the amount of deposits ie controls. ?

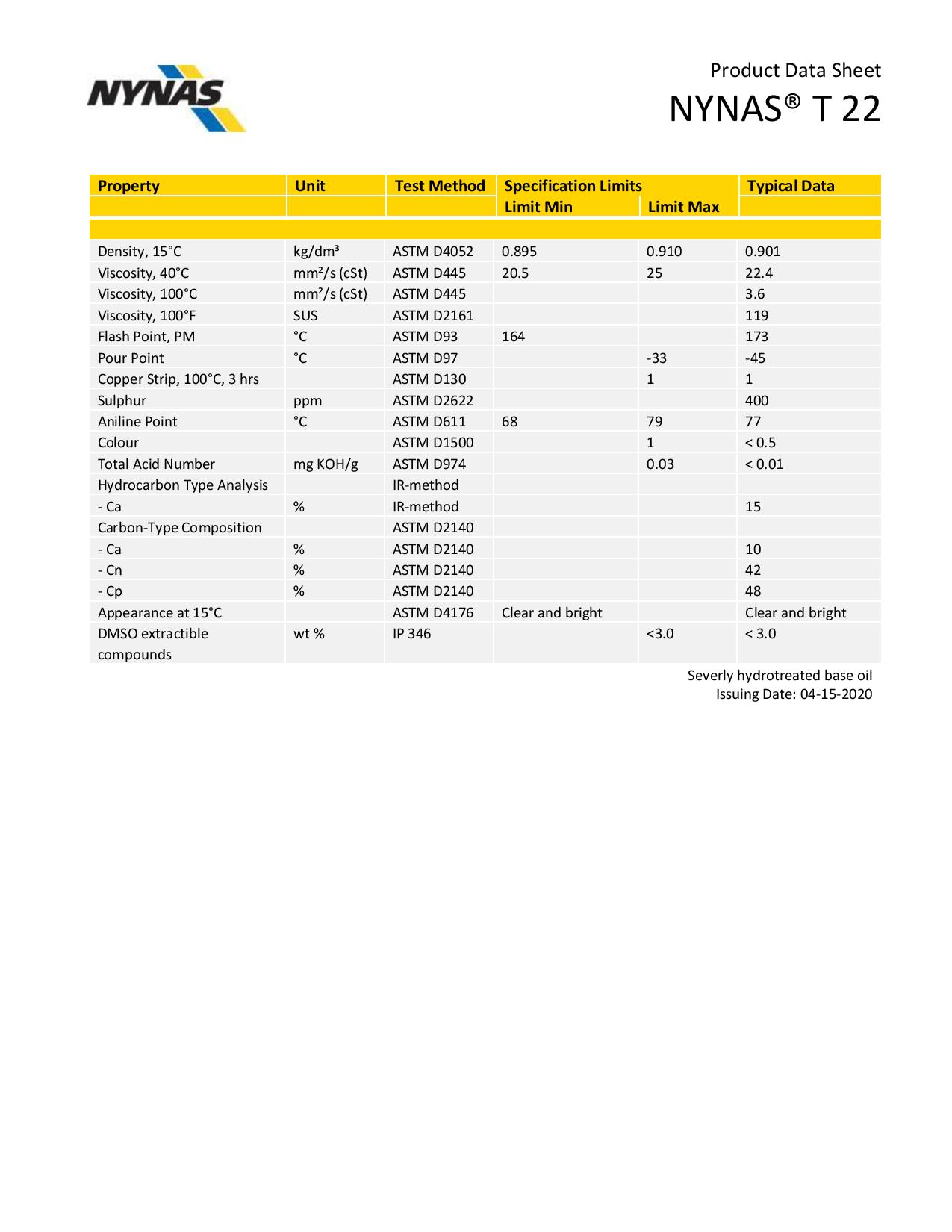

Hatcol 2926 is a Dipentaerythritol ester with linear fatty acids of C5, C8, and C10. It has been used in a leading jet engine oil for over 50 years, and has been used in refrigeration oils, high temperature grease, and various industrial oils. I am not aware of its commercial use in engine oils but that is quite possible. An equivalent is made by Calumet as CalEster F.

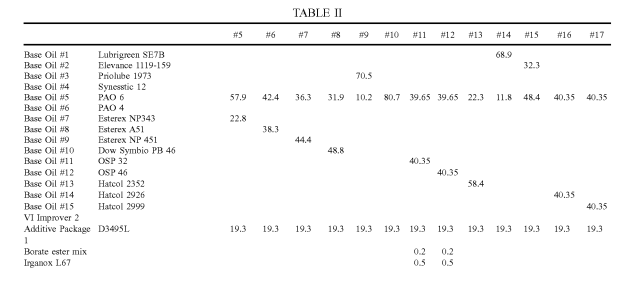

The Hatcol 2926 appears to have performed very well in the data above, although I would prefer Hatcol 2999 (or CalEster 202) for motor oils due to the absence of C5 acid and its higher lubricity. Also Priolube 1973 is a good choice due to its less effect on seals.

The Hatcol 2926 appears to have performed very well in the data above, although I would prefer Hatcol 2999 (or CalEster 202) for motor oils due to the absence of C5 acid and its higher lubricity. Also Priolube 1973 is a good choice due to its less effect on seals.

D

Deleted member 925788

Gość

Yes, Hatcol 2999 can be used in two or four stroke engines. So this has a negative effect on seals? It is related to NPI? I can see these esters have a high aniline point just like mineral oil. Regarding deposit control, which parameter does matter?

I expect the Hatcol 2926 effect on seals would not be too great, and better than some other esters commonly used in motor oils. The Priolube 1973 has a very high NPI (lower polarity) and should have less effect on seals than most other suitable POEs. However, whenever high concentrations of POEs are used, the finished formulation should be tested with the seals being used to assure compatibility, rather than trying to predict the effect from the base ester composition and NPI.

Hatcol 2926 is used in jet engine oils where deposits are a major concern, so it should be in clean motor oil. Hatcol 2999 contains some higher PEs and longer fatty acids, so it should have better lubricity. I would expect both esters should be clean in motor and gear oils.

Hatcol 2926 is used in jet engine oils where deposits are a major concern, so it should be in clean motor oil. Hatcol 2999 contains some higher PEs and longer fatty acids, so it should have better lubricity. I would expect both esters should be clean in motor and gear oils.

Not personally, but have used outside labs for jet engine oils as seal compatibility tests are required by specifications. Different seals are used in different applications and the tests are run under different conditions. Best to check the requirements of the specifications you are seeking to pass.

D

Deleted member 925788

Gość

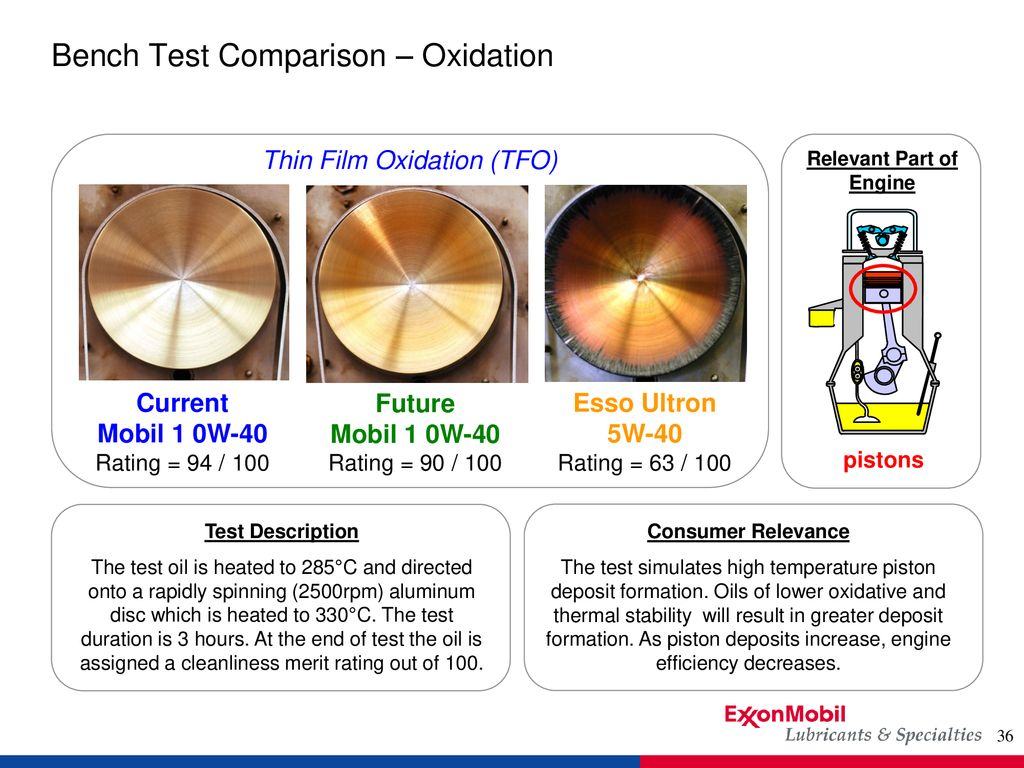

ExxonMobil boasts the following test:

What is your opinion on this test? Does a mixture of base oils play the most important role? Are other components such as AOs or low POE concentration? What is the importance of the N concentration in the formulation?

What is your opinion on this test? Does a mixture of base oils play the most important role? Are other components such as AOs or low POE concentration? What is the importance of the N concentration in the formulation?

Mobil has used that test for many years to develop jet engine oils and they seem to rely on it. It is one of many coking tests that expose a thin film of oil to a hot metal surface. Dynamic coking tests such as this one are better than static tests, such as cooking oil in a small dish in an oven. The base oils are a significant factor for deposits, but also the anti-oxidants. The Nitrogen content usually comes from amine anti-oxidants and dispersants, both of which affect deposits. I don't know how well this test correlates to piston deposits.

D

Deleted member 925788

Gość

On what basis can the N concentration be determined? FTIR? I know in what areas to recognize amine antioxidants (N - H) and PIBSI ashless dispersant, but I do not know what is the basis of it to determine the concentration of this element.

According to my information, there are two areas that indicate the content of nitrogen compounds, i.e. 1360 - 1320 cm-1 and 1400 - 1360 cm-1, N - O, of very high intensity.

Post automatically merged:

According to my information, there are two areas that indicate the content of nitrogen compounds, i.e. 1360 - 1320 cm-1 and 1400 - 1360 cm-1, N - O, of very high intensity.

Last edited by a moderator:

Podziel się: